Our Products

Featured Products

It is fully sealed Dry Conveying System, mounted to the combustion chamber, enhances efficiency through controlled airflow. This counter-flow air re-burns glowing ash, reducing unburned carbon and releasing extra thermal energy. It also heats tar before re-entry, boosting boiler efficiency. Our design ensures superior performance energy recovery.

OSMPPL’s Dry Conveying System is fully sealed to the combustion chamber, utilizing boiler vacuum to draw air in a controlled counter-flow over ash on the conveyor. This promotes re-burning of glowing ash, reducing unburned carbon, while preheating tar enhances thermal efficiency, boosting steam generation and overall boiler performance.

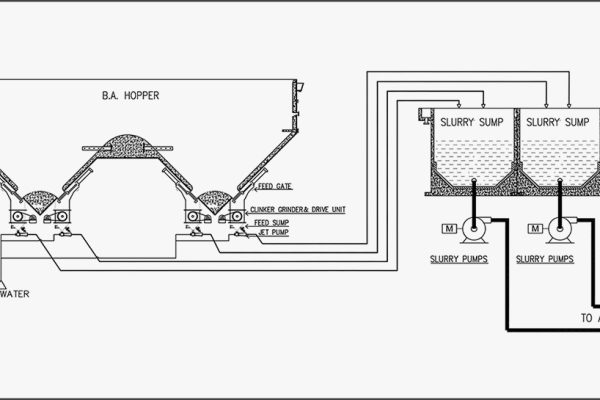

Our advanced Submerged Scraper Chain Conveyor (SSC) ensures continuous, efficient bottom ash removal, even in low headroom areas. Engineered for superior energy efficiency, it outperforms conventional hydraulic systems. With integrated double roll crusher, our system guarantees reliable ash quenching and smooth transfer to slurry disposal or downstream conveyors.

We are a leading manufacturer of dry ventilation systems for tunnels and power plants. Our cabinet-type units feature HDPE wire mesh filters, a centrifugal blower with installation accessories, and GI fabricated housing. The system filters fresh air to 5–20 microns before delivering it efficiently to designated department.

Our upgraded swing valve offers a highly reliable mechanical sealing system, designed as a superior alternative to dome valves. With low-wear seals for extended life, full bore flow for efficient material transfer, and easy maintenance, our leak-proof, glandless design ensures durability, cost-effectiveness, and a clean, safe working environment.

Our track hopper is a hopper-shaped receiver installed beneath rail tracks to efficiently collect material from BOBR wagons or bottom-dump cars. It enables fast, direct unloading, minimizing delays. Using track hoppers helps avoid repetitive demurrage charges, ensuring smooth, cost-effective bulk material handling for rail-based unloading operations.

Our bucket-wheel stacker-cum-reclaimer travels on rail tracks alongside stockpiles, enabling efficient stacking and reclaiming of materials from both sides in two quadrants. Designed for flexibility, it allows selective material handling across different stockpile sections, ensuring continuous, organized, and high-capacity bulk storage and retrieval operations.

Our Continuous Totalizing Automatic Weighing Instrument accurately weighs bulk material on a moving belt conveyor without interrupting flow. It uses variable weight and speed inputs—measuring a small conveyor section's weight and speed via rotary digital pulse generators—ensuring precise, real-time monitoring for efficient bulk handling and process control.

A stockpile serves as an emergency coal reserve, maintained using our high-performance Stacker-Cum-Reclaimer system. When coal wagons are unavailable and bunkers run empty, coal is efficiently reclaimed from the stockyard. Our solution ensures uninterrupted fuel supply, operational continuity, and reliable backup during critical situations in power and industrial plants.

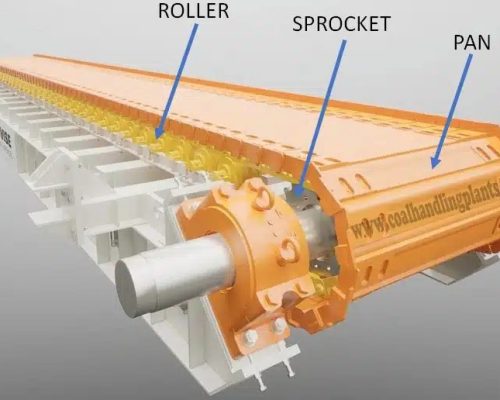

Our Belt Conveyors are integral to automated distribution and warehousing systems. Comprising two or more power-driven pulleys, they efficiently move materials along the belt path. Designed for smooth, continuous operation, our conveyors enhance productivity, reduce manual handling, and ensure reliable, streamlined material transport in industrial and logistics applications.

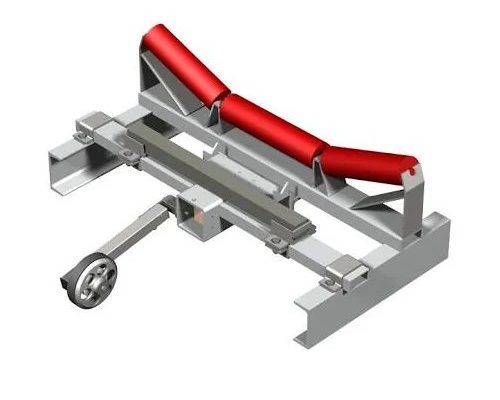

Our conveyor system features a robust fixed frame with various support idlers to ensure smooth belt operation. It includes carrying idlers, self-aligning carrying idlers, impact idlers, return idlers, and self-aligning return idlers—each designed to reduce belt misalignment, absorb impact, and support efficient, reliable material transport across the system.

Our feeders are designed for efficient reclaiming and precise control of bulk material flow from hoppers, silos, and stockpiles. Depending on application needs, we offer various types: apron feeders, belt feeders, reversible belt feeders, and shuttle belt feeders—each engineered for reliable, controlled, and continuous material handling in demanding environments.

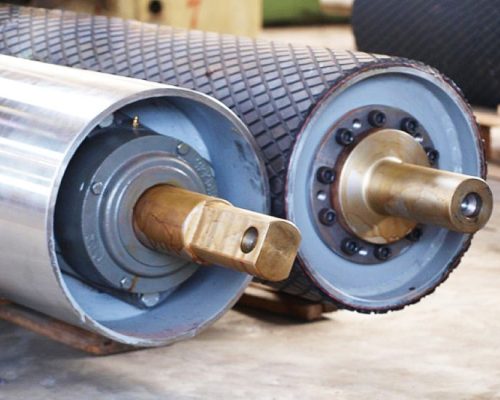

Our belt conveying system is designed for efficient material handling and includes key components such as the head pulley, tail pulley, snub pulley, bend pulley, and take-up pulley. These pulleys work together to maintain proper belt tension, direction, and alignment, ensuring smooth, reliable, and continuous conveyor belt operation.

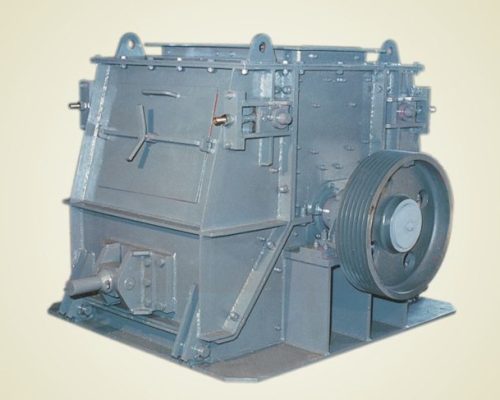

A crusher is essential in material handling, designed to reduce large-sized materials into smaller, manageable lumps. We offer a range of high-performance crushers tailored to various applications, including Reversible Hammer Mills, Double Roll Crushers, 4 Impactors, and Ring Granulators—each ensuring efficient, reliable, and consistent size reduction in bulk processing.

A screen is used to separate crushed coal into permissible sizes before it enters the conveyor system, ensuring efficient downstream processing. We offer two advanced screening solutions: Vibrating Circular Motion Screens for consistent sizing and Flip-Flop Screens for handling moist, sticky materials—both delivering high performance and minimal maintenance.

Our HCSD system features a controlled feeding setup for fly and bottom ash, followed by thorough mixing in an Agitator Retention Tank (ART). Slurry properties are closely monitored for optimal performance. HCSD pumps transport high-density slurry through carbon steel pipelines, with capacity variation and de-blocking ensured for smooth operation.

Our advanced Bag Filter with online pulse jet design ensures efficient dust collection. Contaminated gases enter through a central inlet, slowing velocity to drop coarse particles. Fine dust is captured on filter bags, cleaned by high-pressure air pulses via diaphragm valves. Collected dust settles in the hopper and discharges through the RAV.

We are a leading manufacturer of Air Cooling systems, offering premium Evaporative Air Coolers in Single and Double Skin variants. Our Industrial Air Washer Units cool air by passing it through water-saturated pads, ensuring efficient evaporation. This eco-friendly, energy-saving solution delivers fresh, cool air to ventilated industrial spaces effectively.

Our pipe conveyors offer an eco-friendly, zero-spillage solution for transporting bulk materials across challenging terrains. Ideal for coal, limestone, and dust, they transition from flat to pipe shape using specialized rollers. Capable of handling dual materials, they ensure efficient, cost-effective, and clean conveying over distances up to 7,500 meters.

We are a leading manufacturer of two-stage evaporative coolers, offering superior cooling with lower humidity (50–70%) than traditional systems. Using indirect pre-cooling, they efficiently ventilate spaces like MCC rooms, tunnels, basements, crusher houses, and thermal power stations. Our systems range from 2,000 to 3,00,000 m³/hr for diverse industrial applications.

Spare Parts

OSMPPL’s Dome Valve ensures efficient sealing through static or moving material columns with a unique inflatable elastomeric seal. It prevents leaks, reduces wear, and enhances energy savings. Designed for high-pressure, high-temperature, and abrasive conditions, it guarantees reliable performance. Trusted in 10,000+ installations, it's integral to every OSMPPL system.

OSMPPL offers a range of inflatable seals tailored to specific applications, including food-grade, high-temperature, and harsh environment options. The Dome Valve’s unique closing and sealing mechanism ensures continuous, reliable operation, even where conventional valves fail—making it ideal for demanding industrial conditions requiring durability, precision, and superior sealing performance.

Our Isolation Plate Valves are designed for reliable system isolation, enabling safe maintenance, equipment removal, and controlled shutdowns. Available in manual or pneumatic operation based on application needs, these valves ensure secure sealing, ease of operation, and enhanced safety—making them essential for efficient maintenance in demanding industrial environments.

our Ash Vessel operates on the dense phase pneumatic conveying principle—using high-pressure, low-velocity airflow to move ash in enclosed, plug-like batches. Featuring our engineered Dome Valve and single-body design, it supports multiple feed points and series configurations, ensuring cost-effective, eco-friendly, and efficient ash handling from ESPs and Baghouses.

Our Radio Frequency Level Sensors are engineered for high reliability across diverse material types—conductive or non-conductive, granular, slurry, fine or coarse particles, and contaminated or pulsed liquids. Designed to perform under varying temperatures and pressures, they ensure accurate level detection and consistent operation in demanding industrial environments.

Our Bag Filter Systems efficiently remove particulate matter from process and ventilation air while recovering valuable materials. Trusted globally across industries, our advanced designs enhance conventional bag filters with added versatility and performance. Customizable in size and configuration, they ensure effective dust collection and pollution control for diverse applications.

Our Terminal Box is the final receiving point in a pneumatic conveying line, engineered for enhanced durability and efficiency. Unlike simple pipe terminations, it features a replaceable deflector plate, minimizing maintenance costs. It ensures secure, controlled material discharge into the reception hopper, making it ideal for long-term, reliable operation.

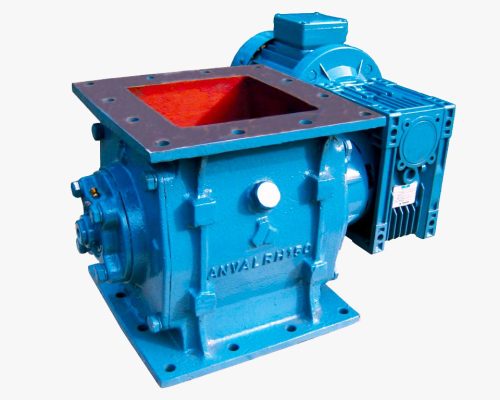

Oor Rotary Feeder features a star-shaped casing for controlled material discharge to ash conditioners or telescopic spouts. Built from heavy-duty, abrasion-resistant steel, it ensures reliable performance under high temperatures. Rounded rotor pockets prevent buildup and enhance flow. Custom-fabricated in-house, our feeders match varied capacities and system requirements efficiently.

Our Ash Conditioners, available in Single/Double Rotary Paddle types, ensure dust-free ash handling by mixing silo-discharged ash with controlled water spray. Slow-rotating paddles create a uniform, earth-moist mix without excess water. Featuring abrasion-resistant paddles, SS nozzles, and integrated motor-drive units, they offer reliable, eco-friendly ash unloading performance.

We manufacture Air Receivers in various capacities and pressures as per IS specifications. These vessels store compressed air, help equalize pressure across the system, and control surges during operation. Built for durability and safety, our air receivers ensure stable, efficient performance in industrial pneumatic systems across diverse applications.

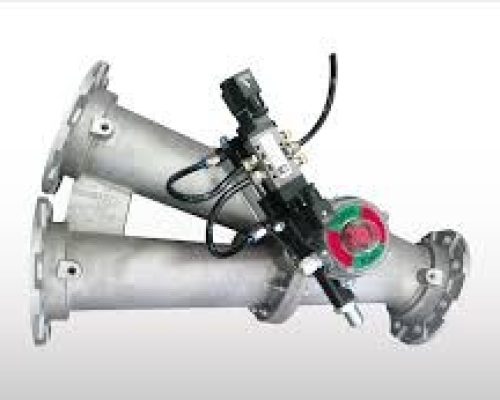

OSMPPL offers a versatile range of product and clean air diverters with deflection angles of 22.5°, 30°, 45°, and 90°. Designed to direct flow between multiple sources or destinations, they feature independent outlet control and deliver high performance, durability, and reliability—benefiting from the proven efficiency of the Dome Valve.

OSMPPL manufactures high-performance Control Panel Boards using premium-quality materials, ensuring durability and efficiency. We offer complete PLC design, testing, and installation services. Built in our modern manufacturing facility, our industrial panels meet the highest standards of quality and reliability, making them ideal for a wide range of industrial applications.